High Capacity (Cv)

The unrestricted flow passage provides high Cv combined with relatively small overall dimensions and light weight compared to the same size globe valves.

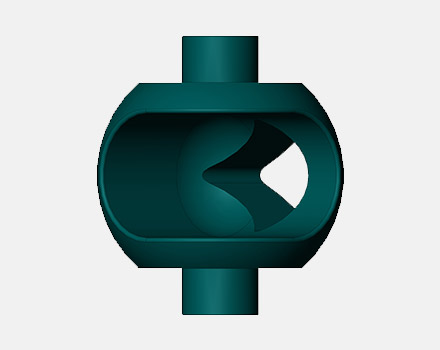

Excellent Flow Characteristics

Precise contouring of the V-notch provides excellent control characteristics for an extensive variety of flow applications.

High Control Precision

The excellent flow characteristic can provide accurate, reliable control in a wide range of applications.

High Rangeability

High rangeability characterization and precise modulation are granted thanks to trim special design.

Good Shearing Capacity

Spring loaded seats design assures scraping action and continuous contact between seat and ball, dirty fluids do not stick and jam on the ball surface, perfect for fiber, slurry and solid applications.

Compact Design

Body construction, special design for stem and actuator connections eliminate free-play (backlash) and assure great resistance even against piping forces.

Low Emission Stem Packing

Special design of stem sealing assures low emission performance to meet fugitive emission and ''TA-Luft'' requirements.

Fast Operating Time

Quarter turn design allows to use fast actuating devices which can perform emergency operation in a few second to improve the safety of the plant.

Fire-Safe Design

The control ball valves can be supplied with API6FA, API 607 and BS 6755 part 2.